How Is The Proper Size Figured For A Wood Lathe Tool Figured

What type of lathe should I purchase?

As the author of several books on woodturning, the designer of a lathe (the Conover Lathe, no longer in production) and a founding board member of the American Association of Woodturners (I'g member #004), it might be an understatement to say that people oft ask my communication about which lathe to purchase or which lathe is the all-time. They ever want a simple reply, like "Buy an Acme Model XJ4, as purchased by Wile Due east. Coyote in the Warner Brothers 'Route Runner' cartoons."

Information technology's not that uncomplicated. What yous need depends on your upkeep, infinite and turning goals. Do you want to practice by and large spindle turning (creating a cylindrical object)? Or faceplate turning (using a metal disc, the faceplate, to attach wood to your lathe and so yous tin turn an item that can't exist secured simultaneously on the headstock and tailstock)? Volition turning exist your main woodworking pastime, or are you ownership a lathe to augment your full general woodworking?

Types of Lathes

Today, lathes come in three flavors: mini, midi and fullsize, each with strengths and weaknesses that brand them more or less appropriate for certain kinds of turning tasks.

For example, mini lathes are great for turning pens, small-scale items and miniatures. Midi lathes are more appropriate for creating furniture spindles and medium bowls. And full-size lathes tin can tackle whatever turning task.

However, but every bit dog breeds range from chihuahuas to Newfoundlands but all share an essential "dog"-ness, there are elements that make a lathe a lathe.

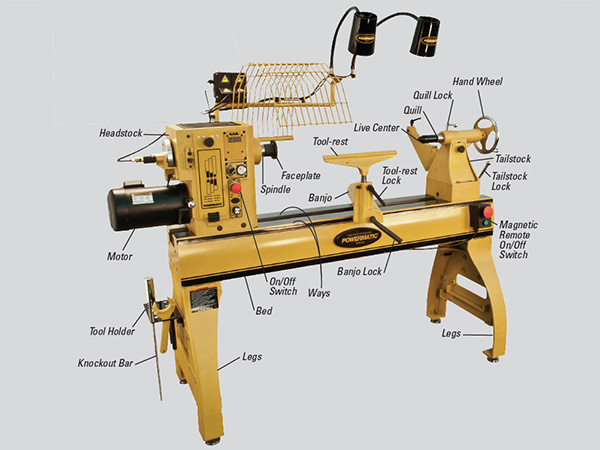

Modern lathes have a bed made from cast-iron or welded steel, the superlative of which sports a set of ways: two parallel strips of constant width and spacing on which the headstock, tailstock and banjo (tool base of operations) are mounted. While the headstock is fixed at one cease of the bed, the tailstock and banjo are free to slide on the ways to accommodate the turner's application. Lathes come with at to the lowest degree one tool-residue, a drive center, a alive center and a faceplate.

Information technology is fair to annotation that increases in price usually mean improvements in usability. Equally you pay more, the machine gets heavier, with friendlier controls. For example, very depression-cost lathes tend to have levers on the banjo that collide with each other, making adjustment difficult. Paying more than gets y'all a tailstock, banjo and tool-residuum that lock without undue strength being necessary.

If y'all're in the market for a lathe, allow'south look at what else you should be looking for.

Choosing a Lathe: Capacities That Matter

Spindle Diameter: All mini and midi lathes have a i″ spindle with eight threads per inch. While this is more than adequate for turning furniture spindles and bowls up to about 12″ in diameter, information technology is non acceptable for heavy faceplate work. That is because a 1″ spindle tin flex between the headstock bearings with the loftier forces exerted during heavily laden faceplate work.

Therefore, most large lathes use either a i-1/4″ or a 33 mm spindle (still with eight threads per inch). Converted to decimals, these spindle sizes are 1.250″ and ane.299″ — very close. What the .049″ difference does is to increment the rigidity over 1″ from 2.44 times to 2.85 times, because the stiffness of a circular bar increases by a ability of four as diameter increases. Pocket-size increases in diameter noticeably increase force. Withal, this is not enough difference to choose one spindle over the other.

Swing: Manufacturers list the "swing" measurement as twice the center height — what the machine volition swing over the bed. The true swing of a lathe, however, is center elevation over the banjo, considering this base for the tool-residue has to exist under all spindles and virtually faceplate work. Two lathes with the same swing could take different banjo heights. Many manufacturers do now listing swing over banjo likewise as over the bed, but information technology pays to check.

If your primary goal is to spindle turn piece of furniture parts, you are unlikely to need to turn bigger than a 4″ diameter, so a vi″ swing over the banjo is more than adequate.

Center to Center Altitude: Betwixt center altitude is oft listed as the measurement that results when computing the distance from the lathe's spindle nose to its tailstock nose, with the tailstock affluent with the stop of the bed. You need to realize though, that the drive and live centers needed to hold a spindle while you're turning lessen this altitude considerably. Many manufacturers are now listing the true between-center distance with the lathe's supplied centers.

That existence said, most supplied centers on mini and midi lathes are inferior. This is peculiarly truthful of the live middle; upgrading to a ameliorate ane volition lessen the eye to middle distance by as much as 3″. In most cases, you can also gain dorsum an inch or 2 of space by hanging the tailstock off the bed by this amount.

If your goal is to use your lathe in a home workshop to spindle plow furniture parts, you'll demand a lathe that has 29″ to 36″ between centers.

Power and Speed Controller: Electric motor ability ratings are often overstated. Mostly, multiplying near mini and midi lathes' stated power by virtually .75 volition get yous a lot closer to the actual power. The reason for this is that the maximum horsepower rating tin can but be maintained for a few seconds before the motor burns upwardly. What really counts is the continuous rating.

The Europeans list motor ability in kilowatts, a much fairer value of the continuous, or true, power. Since there are 745.7 watts in a horsepower, it is easy to figure out the horsepower from a kilowatt rating.

Mini lathes come with a 1/2hp motor, which is probably closer to 1/3hp simply is more than than adequate for this size lathe. Midi lathes typically are outfitted with a 1hp motor, merely this delivers closer to 3/4hp at the spindle. The fact that almost all variable-speed mini and midi lathes have a DC (direct current) motor and controller contributes to this. Again, this is generally sufficient for home workshop and small furniture store needs.

Modern full-size lathes have a minimum of a 1-1/2hp iii-stage induction motor linked with a variable frequency drive (VFD). A VFD takes your unmarried phase 60 hertz house current and converts it to 3-stage current at whatsoever bike charge per unit betwixt 2 and 60 hertz. Since the speed of an induction motor is controlled by the phase charge per unit of the current, this allows accurate speed command with negligible loss in power at depression speeds. DC motors and controllers, in contrast, have a more pronounced ability drop-off at low speeds.

VFDs as well allow a remote switch to be attached to the controller. This allows a second set of stop and start switches to be magnetically fastened anywhere the turner deems user-friendly. This is both a nice convenience and a prophylactic gene.

All 2hp and larger motors volition require a 220-volt outlet. All mini and midi lathes will run on 120 volts.

Weight: When it comes to lathes, weight is considered advantageous. Vibration is inversely proportional to weight, so heavy cast-fe machines tend to soak upwardly vibration. In the terminal twenty years, however, machines made from welded steel — especially the bed — take come to the forefront. If designed properly, the welds act like a crack in a wine drinking glass and stop vibration.

Three Lathe Classes

Equally I mentioned before, today at that place is a broad offer of mini, midi and total-size lathes. Permit us take a wait at each of the categories in plough.

Mini Lathes: During the last decade of the 20th century, a number of manufacturers brought out pocket-sized demote lathes with a brusque bed. Aimed at the rising tide of pen turners (the first pen kits came out in 1987), they were dubbed "mini lathes." These small lathes found keen popularity with model makers, teenagers and those just wanting to try turning without spending a fortune. Mini lathes typically have a 1″ – 8 spindle, 8″ to 10″ swings and 12″ to xv″ between centers.

The cheapest mini lathes merely have four or five caster steps for speed control; better ones have a DC motor and controller. While the only article of furniture part y'all can plough on the boilerplate mini is a knob, bed extensions are bachelor for many of them. With a bed extension, a mini can be morphed into a bench lathe usable for nigh furniture piece of work. If you just desire to effort turning, a mini can be a great first stepping stone to a great hobby. Besides, it is a sensible choice if y'all have a child that wants to plow or if your ambitions are strictly pens and miniatures.

Midi Lathes: During the first 10 years of this century, many manufacturers beefed up the bed of their mini lathes and raised the ane″ – 8 spindle height to yield a 12″ or better swing. The delineation of mini existence 10″ or smaller and midi being 12″ and bigger is now office of the pop lexicon. A midi lathe would be Goldilocks' option: not too big, not likewise small-scale, enough center to center distance with a bed extension, adequate variable speed power and a reasonable cost. A recent trend is to too step the banjo and tool-rests up to i″, which adds rigidity and allows swapping of tool-rests with bigger machines.

Midi lathes are, in fact, pretty much the standard workshop bench lathes of my youth with variable speed in nigh all cases. Happily, near all companies offer stands likewise.

Typically, adding ane extension increases the olfactory organ-to-nose distance between the spindles to between 36″ and 45″. A midi lathe is a keen choice for furniture builders but is still neat for pens and miniatures. You can turn tiny things on a large lathe, but non vice versa. Midis are also very acceptable for basin turning (if this is your goal, forget the bed extension). The ane″ – 8 spindle and ability does limit the midi to light faceplate work: you can only plough bowls upward to virtually 12″ in diameter.

Total-Size Lathes: The really big lathes in this category once catered to millwork shops and blueprint makers, merely today they are the choice of serious hobby turners, especially bowl turners. Most full-size lathes now sport modular beds that can be extended for very long work with swings over the bed every bit big as 24″.

This means they can turn anything from porch posts to huge bowls. All have a minimum of 1.5hp motors, only virtually sport 2hp, with 3hp being an optional upgrade. Industry standard is now VFD speed control. Full-size lathes tin exercise it all.

Near of the total-size lathes at present have the ability to slide the headstock shut to the end of the bed, turning them into "bowl lathes." The thought is to make the bed shorter, allowing the woodturner to stand where the headstock would normally exist, giving them swell access and leverage during turning. If you turn a lot of bowls, particularly large ones, the advantage of this setup cannot be overstated. (Another solution is the ability to turn the headstock nose near 45˚. This allows slightly more faceplate swing and much ameliorate access during faceplate work, just it is not equally good as a truthful bowl lathe.)

Setting Upward Your Lathe

Once y'all've brought your new lathe domicile, it's time to fix information technology up. If it's a mini lathe, one of the attractions for the small shop owner is that y'all can store information technology under a bench when non in use. When information technology comes to use, however, you will find the lathe works better if you braze it to the demote in some way. C-clamping each end or grabbing each end in the dogs of a workbench are great options. If you cannot clench directly to the lathe, bolting the lathe to a 3/4″ slice of plywood that tin can then be clamped to the bench is a workaround.

When it comes to larger lathes, most shop owners place them against the wall. This may be all correct for spindle piece of work, but information technology limits faceplate work. I think it's ameliorate to place a lathe abroad from, or at to the lowest degree at right angles to, a wall. You will demand about 24″ of clearance between the headstock and the wall to accommodate the knockout bar.

Leveling Your Lathe

Proper leveling is probably 1 of the near overlooked factors in setting up a lathe. It should be level along the length of the means and beyond the ways at each cease. Beyond at each finish is most important, because unlike states of level at each end of the lathe may introduce a twist into the bed (often the reason centers don't align properly). A expert architect's level is a sufficient tool for this task. Simply adjust the leveling screws in the lathe's stand or legs and then that the ways are level end to end. Now, alternately identify the level across the ways but in front of the headstock and at the reverse end, and adjust the screws until each cease is dead level. It is best if you do non accept to move the lathe later on leveling.

Budgeting for Tools

When buying a lathe, you likewise need to upkeep for tool sharpening systems and tools — which tools depends on your woodturning goals. (Mini lathe users can get by with cheaper miniature tools.) I've compiled my recommendations for tools for both spindle and faceplate turning into a spreadsheet, bachelor online.

I prefer to purchase turning tools advertising hoc, rather than in sets, which can include tools you will never use or workhorse tools in the wrong size. Avoid bargain basement carbon steel sets and, unless your turning ambitions are very modest, avert carbide tools. Here's why: If you but want to turn a few projects, they're an economical choice because y'all volition not have to buy a grinder and the jigs necessary to sharpen conventional tools. On the other mitt, they'll never exit the crisp edges, burnished surfaces or refined beads in spindle work that properly sharpened conventional tools will.

I suggest buying tools made from high-speed steel, or from powdered metal, which offers even more edge holding time betwixt sharpening.

Yes, you lot will have to sharpen your tools, using a bench grinder to grind them to the proper shape. (They seldom come up that way.) Buy as practiced a grinder every bit yous can afford, such as a deadening-speed grinder that comes with aluminum oxide wheels. A buffer is great for honing spindle tools after grinding.

Rubber Equipment

Y'all'll too need to consider rubber equipment and condom practices. Minimum middle protection for turning is eyeglasses, with side shields, that run into ANSI Z87.i standards. If y'all wearable prescription glasses, your optometrist can make you a pair that meet the Z87.ane standards, or y'all tin article of clothing clear glasses that run into the standard over your prescription glasses. An even better option is to wearable a confront shield that meets the Z87.1 standard — most actually exceed it.

Hearing protection during most turning is wise. Roughing out work, as you starting time your project and quickly remove textile from your eventual bowl or a spindle, can emit sound over 80 decibels every bit the tool is alternately cutting woods and air.

Grit protection is well-nigh problematic around lathes, and then annihilation that can exist done to suck up grit before it gets into your lungs is expert. You lot can put the hose from a HEPA vacuum most where you lot're working to capture a lot of the dust. Support this dust collection option past wearing an automotive type dust mask or, even better, a respirator.

And, when it comes to turning on your lathe, don't be a speed demon. Faceplate piece of work never needs to exceed 1,200 rpm, with 150 to 800 rpm for initial roughing.

Spindles upwards to ii″ need an initial speed between 500 and 1,400 rpm, depending on the skill and feel of the turner.

All this is to say that the lathe is only the tip of the iceberg. The best of lathes is useless without equally good tools. Many give up on turning considering they never properly shaped and sharpened the tools, and then a proper grinder and jigs are a necessity. I know a few turners who had to quit because they inhaled too much grit. Wait at the total package, and non just the lathe.

How Is The Proper Size Figured For A Wood Lathe Tool Figured,

Source: https://www.woodworkersjournal.com/choosing-the-best-woodworking-lathe-for-your-shop/

Posted by: munnmorofter1970.blogspot.com

0 Response to "How Is The Proper Size Figured For A Wood Lathe Tool Figured"

Post a Comment